Ground source heat pumps are an established renewable heating option for the domestic market with good efficiencies and minimal maintenance requirements. Many people are familiar with closed-loop ground source in which an anti-freeze solution is pumped through buried pipework to extract heat directly from the ground. However, there is a second option which is often overlooked and under represented – open-loop in which heat is extracted from groundwater before the water is returned to the aquifer from which it was taken.

Closed-loop systems are more prevalent as they can be installed virtually anywhere. Open-loop on the other hand requires access to an adequate water supply or aquifer.

The lack of understanding of open-loop systems and their potential is one of the barriers to the wider adoption of this technology. This article aims to dispel some myths and highlight the additional benefits of installing open-loop systems, using dedicated open-loop heat pumps.

"Open Loop systems are only cost effective in large commercial installations due to the amount of water required and associated abstraction licence and discharge permit requirements."

This statement is incorrect. H.D. Services install the Soleco Open-Loop GSHP unit, which is designed to be used with groundwater as a heat source. As a result, it does not require conversion (an additional plate heat exchanger) or huge amounts of flow.

Most heat pump units are designed to be used with ground arrays and anti-freeze solutions and if they are converted to use groundwater as a heat source, they tend to lose efficiency and require a larger amount of flow than a dedicated open-loop unit.

What makes the Soleco unit ideal for domestic installations is the fact that it requires a relatively low flow rate. In the nine years we have been installing the units, we have not required an abstraction licence for any of the domestic installations we have completed as the amount of water abstracted has not exceeded 20 cubic metres (20,000 litres) per day. Domestic open-loop GSHP systems may require either a discharge permit or a registration of exemption for a discharge permit from the Environment Agency.

It is also important to remember that as an MCS approved product, as long as the installation is carried out by an MCS approved installer, it is likely to be eligible for the renewable heat incentive if the rest of the eligibility criteria are met. This could repay 100% of the initial costs.

"Open-Loop systems are less efficient."

Again, this statement is incorrect. Dedicated open-loop GSHP units are generally more efficient than their closed-loop counterparts. The myth lies in the fact that closed-loop units can be converted to use groundwater; however this negatively affects the efficiency of the closed loop unit. It must also be considered that the groundwater abstracted from a depth of at least 10 metres below ground level is at a constant temperature throughout the year and is not subject to seasonal temperature variations; the source and temperature are constantly replenished. A Soleco GSHP will take ground water at approximately 11°C and return it at about 7°C. A closed-loop system cannot guarantee a specific ground temperature at extraction due to the repeated use of the same loop-pipe and fluid.

"Open-loop systems are more expensive to install."

This is only true in some cases as the cost of an open-loop system is dependent upon the depth from which water is available beneath a site. The heat pump units themselves are not significantly more expensive.

In the South East, where the largest chalk aquifer in the UK is located, it is imperative that a drilling technique is used which will not block fissures and reduce flow through the borehole. Many closed-loop boreholes utilise the direct-circulation rotary drilling technique which is fine as no flow through the borehole is required. This technique is not best suited for the construction of water supply boreholes in chalk as the circulation fluid carrying cuttings can block the fissures thereby reducing the flow of water into the borehole.

The method preferred by the Environment Agency when drilling into the chalk aquifer is cable-tool percussion. This drilling technique takes longer than rotary drilling. However, it is a tried and tested method and if the borehole is properly designed and the chalk found to be stable, the borehole could remain 'open' indefinitely.

The benefits of Open-Loop installations for domestic customers

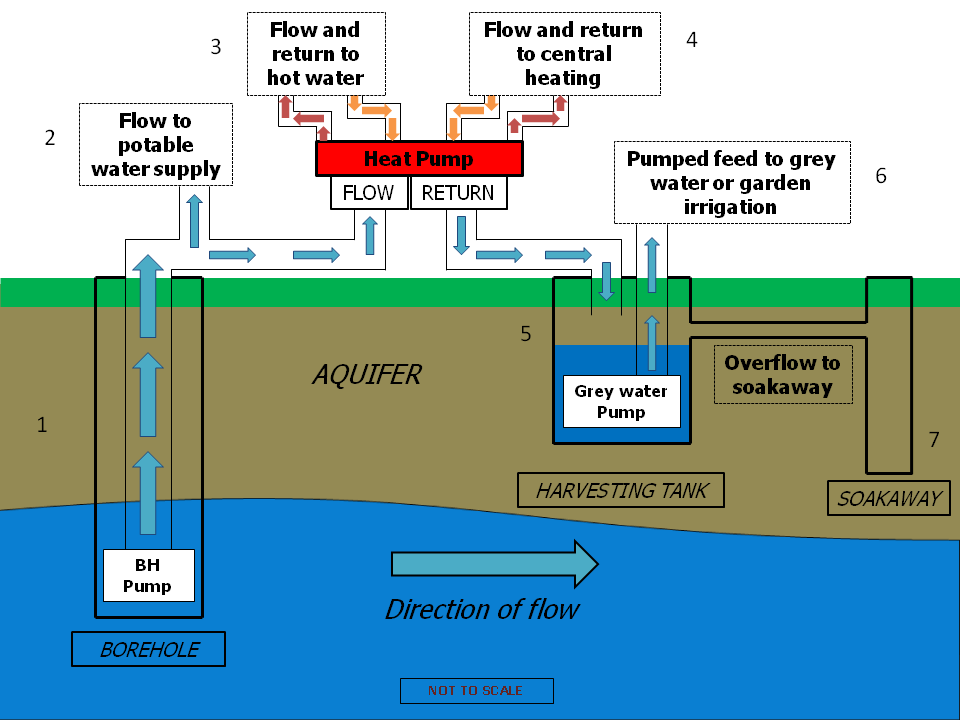

There are additional benefits in utilising groundwater as a heat source as the water can be put to other uses. For those building or renovating their homes, or without access to mains water, an independent water supply can be a great advantage and also result in savings on water bills.

Flow can be diverted prior to entering the heat pump unit to feed a potable water supply (subject to analysis and suitable filtration). Once the water has passed through the heat pump and heat extracted for the heating and hot water systems, the cooled water is generally returned to the aquifer.

It is possible to link the discharge from the heat pump to a buried harvesting tank prior to return to the soakaway. This process not only allows the water to regain some heat before returning to the aquifer but means that water from the tank could be used as grey water or for irrigation. Unlike rain water harvesting tanks that are only replenished when it rains, a heat pump harvesting tank is replenished whenever the heat pump is in operation.

To enable people to make an informed decision regarding the best ground source heat pump option for them, it is imperative that the industry begins to recognise the benefits of open-loop ground source technology within the domestic market and the additional benefits to customers that this option offers. It is up to all of us to present the best technological solutions and allow people to make informed decisions on how best to meet their needs and spend their money.

For further information, discussion or advice please contact H.D. Services Ltd on 01494 792000 or via enquiries@thehdgroup.co.uk